Because of the performance, durability and versatility of polyurethane materials, it is no surprise that our aromatic isocyanates and our polyols are the main building blocks in many products that surround us every day. As a matter of fact, our basic polyurethane chemicals can be found in applications as diverse as:

- Industrial coatings.

- Waterproofing coatings for concrete.

- Adhesives for automotive, construction, packaging and general assembly.

- Construction Sealants

- Rigid foam insulation and spray foam.

- Packaging foam.

- Hydrophilic foam.

- Rubber crumb binders for athletic tracks, playgrounds and molded products.

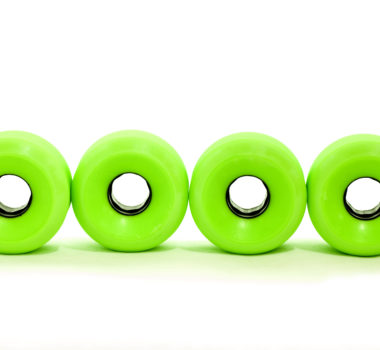

- Hard elastomers (e.g. wheels).

- Soft or microcellular elastomers.

- Truck bed liners.

- Gel pads for comfort and pressure relief in medical fields.

- TPU.

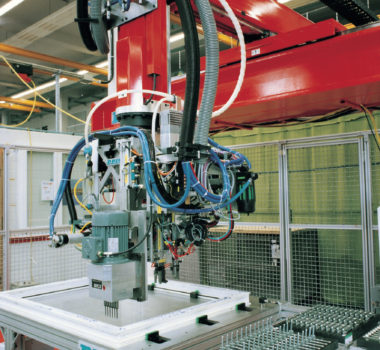

With such a variety of applications, and with new uses constantly being developed, it is easy to realize that one size does not fit all when it comes to polyurethane raw materials for the CASE segment. Formulators need access to a large selection of isocyanate blends, derivatives and prepolymers, as well as polyols covering a full range functionalities, molecular weights and reactivity to create unique products for their respective fields.

At BASF, we understand this necessity, and, for this reason, we pride ourselves in offering one of the most comprehensive portfolios of CASE polyurethane raw materials in the industry. Our catalogue includes standard and specialty grades of aromatic isocyanates and polyether polyols (conventional and graft) that complement each other and offer to formulators the right tools to fine tune the properties of their systems and formulations. And if the right material does not already exist, our technical teams stand ready to create it, helping our customers taking their ideas and innovations to the next level.

By combining the breadth of our product portfolio with our innovative mindset, with investments in our plants, and with a dedicated technical service group focused on helping our customers with the safe and optimal use of polyurethane chemicals, our CASE team is all about delivering solutions that support the success of our CASE customers and the growth of your business.

Common Products by Market and Application

| Coatings | |

|---|---|

| 1K Primers | 5310, 5020, 5230 |

| Automotive | M20, TF2115 |

| Packaging/Laminating | M, MI, M20, 5143 |

| Polyurea | 5060, 5080, 5380 |

| Spray | MI, M20, 5080, 5090, 5143, 5380 |

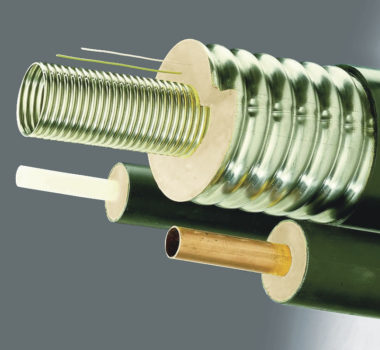

| Tanks and Pipes | M10, M20, 5143, 5380 |

| Sealants | |

|---|---|

| Floor | M, MI, M10, M20, LP30, T80 |

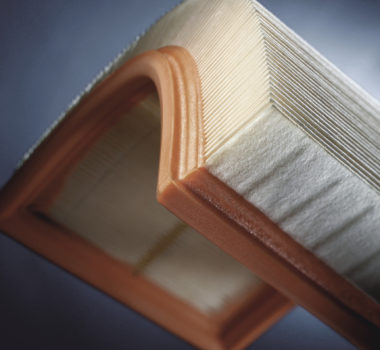

| Gaskets | MP102, 5040, 5050 |

| Transportation | M, MI, M10, M20, LP30, 5143, 234, T80 |

| Tanks and Pipes | MI, M20, MM103, 5080, 5143, T80 |

| Adhesives and Binders | ||||

|---|---|---|---|---|

| Concrete | M20, 230, 234, 255, 266 | |||

| Construction | M, MI, M10, M20, 81 | |||

| Foundry Core | M20, M70L, 78, 266 | |||

| Hot Melt | M, MI, LP30 | |||

| Packaging/Laminating | M10, M20, MM103, MP102, 234, 5090 | |||

| Rubber Crumb Binders | M, MI, 223, 5020, 5230, 5310 | |||

| Transportation | M10, M20, 234, T80 | |||

| Elastomers | ||||

|---|---|---|---|---|

| Clear Elastomers | MP102 | |||

| Soft Elastomers | MM103, MP102, 5030, 5050, 5070, 5143 | |||

| Hard Elastomers | M20 | |||

| High Abrasion Elastomers | 5030, 5070, 5090 | |||

| Low Temperature Stable Kits | 5080, 5090, 5143 | |||

| TPU | M | |||